Managing inventory accurately is no longer optional—it is essential. Whether you run a retail store, pharmacy, warehouse, or small distribution business, stock errors can directly impact revenue, customer trust, and daily operations. This is why more businesses are shifting toward a barcode inventory system.

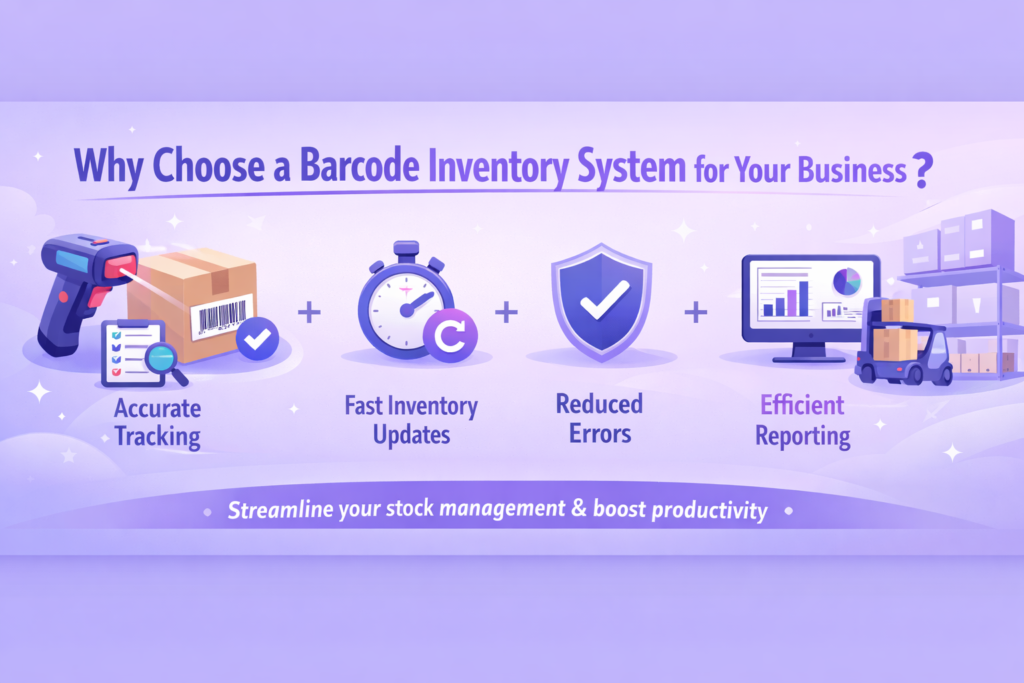

According to current AI Overview–driven search insights, businesses are actively looking for smarter, faster, and error-free ways to manage stock. A barcode-based inventory system answers this demand by offering real-time visibility, improved accuracy, and simplified inventory control. Let’s explore why choosing a barcode inventory system is a smart move for modern businesses.

What Is a Barcode Inventory System?

A barcode inventory system uses barcodes and barcode scanners to track products as they move in and out of stock. Each product is assigned a unique barcode that contains essential information such as product name, SKU, batch number, and quantity.

When scanned, the system instantly updates inventory records in real time. This eliminates manual entry, reduces errors, and ensures that stock data is always accurate.

Why Businesses Are Moving to Barcode Inventory Systems

Accurate Stock Tracking in Real Time

One of the biggest reasons businesses adopt a barcode inventory system is accuracy. Manual inventory tracking often leads to mismatches, missed entries, or outdated stock data.

With barcode scanning:

Stock updates instantly

Human errors are reduced

Inventory levels stay accurate at all times

Real-time tracking allows businesses to know exactly what is available, what is running low, and what needs restocking.

Faster Operations and Improved Efficiency

Speed is a key factor in today’s competitive market. A barcode inventory system significantly reduces the time spent on stock counting, billing, and order processing.

Instead of searching for products or updating registers manually, staff can scan items within seconds. This improves checkout speed, warehouse operations, and internal workflows—making daily operations smoother and more efficient.

Reduced Human Errors

Manual inventory processes often lead to mistakes such as incorrect stock entries, pricing errors, or missing products. Barcode systems minimise these issues by automating data capture.

Each scan pulls accurate product data directly from the system, ensuring consistency across inventory, billing, and sales records.

Better Inventory Control and Planning

A barcode inventory system provides clear visibility into stock movement. Businesses can easily track:

Fast-moving products

Slow-moving or dead stock

Seasonal demand patterns

Overstock and under stock situations

With these insights, businesses can plan purchases better, avoid over-ordering, and reduce losses due to expired or unsold products.

Easy Integration with Billing and POS Systems

Modern barcode inventory systems integrate seamlessly with billing software and POS systems. This creates a single, connected workflow for sales, inventory, and payments.

When a product is billed:

Inventory updates automatically

Sales data is recorded instantly

Reports are generated without manual effort

This integration improves operational accuracy and saves valuable time.

Scalable for Growing Businesses

As a business grows, inventory becomes more complex. A barcode inventory system scales easily with business expansion.

Whether you add new products, open more outlets, or increase stock volume, the system adapts without disrupting operations. This makes it ideal for small businesses planning long-term growth.

Improved Customer Satisfaction

Customers expect quick service and product availability. A barcode system helps businesses serve customers faster and more reliably.

Accurate stock data ensures:

Products are available when needed

Billing is quick and error-free

Customers face fewer delays

This improves customer trust and encourages repeat business.

Cost Savings in the Long Run

Although implementing a barcode inventory system requires an initial setup, it helps reduce long-term costs by:

Minimising stock losses

Preventing over-purchasing

Reducing labour time

Lowering operational errors

Over time, these savings contribute directly to better profitability.

Why Barcode Inventory Systems Fit AI Overview Search Intent

AI Overview–driven searches focus on clear benefits, practical use cases, and decision-making support. A barcode inventory system matches this intent by offering:

A clear solution to inventory errors

Easy-to-understand implementation

Immediate operational benefits

Long-term business value

This is why “barcode inventory system” continues to appear in high-intent business and retail searches.

Who Should Use a Barcode Inventory System?

A barcode inventory system is suitable for:

Retail stores

Pharmacies

Warehouses

Supermarkets

Manufacturing units

E-commerce sellers

Any business that handles physical stock can benefit from barcode-based inventory management.

Final Thoughts

Choosing a barcode inventory system is no longer just about convenience—it’s about business efficiency, accuracy, and growth. In an era where speed and data accuracy define success, barcode inventory systems provide a strong foundation for modern operations.

By reducing manual work, improving stock control, and integrating smoothly with billing systems, barcode inventory solutions help businesses stay competitive and future-ready