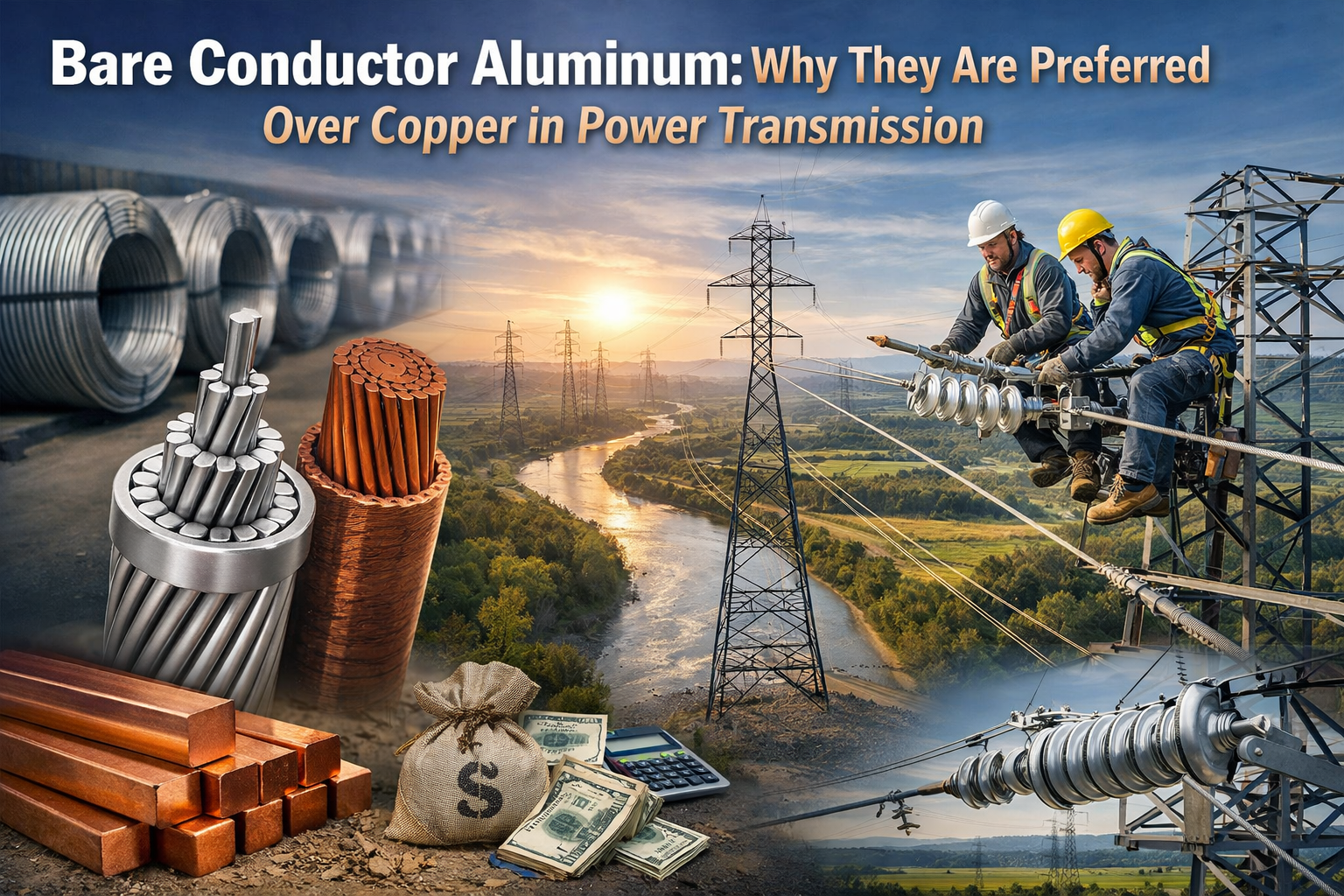

Bare conductor systems play a critical role in modern power transmission and distribution networks. From long-distance overhead lines to substation connections, bare conductors are trusted for their electrical efficiency, mechanical strength, and cost-effective performance. For engineers, utilities, and procurement professionals, selecting the right bare conductor is a strategic decision that directly impacts grid reliability, safety, and lifecycle cost.

In this guide, we explore what bare conductors are, their types, applications, selection criteria, and why working with a proven manufacturer like HNBF Power ensures long-term value for power infrastructure projects.

What Is a Bare Conductor?

A bare conductor is an electrical conductor without insulation, typically used in overhead transmission and distribution systems. Because it is exposed to air, it relies on proper spacing, mechanical design, and installation practices to ensure safe and reliable operation.

Bare conductors are widely used by:

- Power utilities and grid operators

- EPC contractors

- Industrial power projects

- Rural electrification and renewable energy networks

Their design prioritizes current-carrying capacity, tensile strength, corrosion resistance, and compliance with international standards.

Common Types of Bare Conductors

Different power applications require different conductor constructions. The most widely used bare conductors include:

AAC – All Aluminum Conductor

AAC conductors are made from high-purity aluminum and offer excellent electrical conductivity. They are commonly used in urban distribution networks where span lengths are shorter and corrosion resistance is important.

AAAC – All Aluminum Alloy Conductor

AAAC conductors use aluminum alloy to provide higher mechanical strength than AAC while maintaining good conductivity. They are suitable for longer spans and areas with higher wind or mechanical loads.

ACSR – Aluminum Conductor Steel Reinforced

ACSR conductors combine aluminum strands with a steel core, offering high tensile strength and durability. They are widely used in transmission lines, river crossings, and long-span installations where mechanical performance is critical.

As a global bare conductor manufacturer, HNBF Power supplies AAC, AAAC, and ACSR conductors tailored to international utility and EPC requirements.

Key Applications of Bare Conductors

Bare conductors are essential components across multiple power infrastructure scenarios:

- Overhead transmission lines for high-voltage and extra-high-voltage networks

- Overhead distribution systems in urban and rural areas

- Substation busbars and jumpers

- Railway electrification systems

- Renewable energy grid connections, including wind and solar farms

Their open-air installation allows efficient heat dissipation, enabling higher current capacity under proper design conditions.

Technical Factors to Consider When Selecting a Bare Conductor

Choosing the right bare conductor involves balancing electrical, mechanical, and environmental factors:

Electrical Performance

Current-carrying capacity, resistance, and power loss must align with system voltage and load requirements.

Mechanical Strength

Tensile strength, sag characteristics, and span length are critical for overhead line safety and stability.

Environmental Conditions

Temperature variation, wind pressure, ice loading, and corrosion potential all influence conductor selection.

Standards & Compliance

Bare conductors should meet international standards such as ASTM, IEC, BS, or customer-specific utility specifications.

HNBF Power supports engineers and procurement teams by providing technical data, customization options, and compliance documentation for global projects.

Advantages of Using High-Quality Bare Conductors

- Cost-effective power transmission with low material and installation costs

- High reliability for long-term grid operation

- Flexible design options for different terrains and climates

- Ease of inspection and maintenance

- Proven performance in utility-scale applications

When sourced from an experienced bare conductor supplier, these advantages translate into lower total project risk and optimized lifecycle cost.

Why Choose HNBF Power as Your Bare Conductor Manufacturer?

HNBF Power is a trusted global manufacturer of overhead conductors and power cables, serving utilities, EPC contractors, and industrial clients worldwide. With advanced production facilities and strict quality control, HNBF Power delivers:

- AAC, AAAC, and ACSR bare conductors customized to project specifications

- Consistent quality aligned with international standards

- Engineering support for conductor selection and design optimization

- Reliable supply for large-scale transmission and distribution projects

By partnering with HNBF Power, buyers gain both technical confidence and supply chain reliability.

FAQs About Bare Conductors

1. What is the difference between AAC, AAAC, and ACSR bare conductors?

AAC offers high conductivity with lower strength, AAAC provides better mechanical performance, and ACSR delivers the highest tensile strength using a steel core for long spans.

2. Are bare conductors safe for power transmission?

Yes, when properly designed and installed with correct clearances, bare conductors are safe and widely used in global power networks.

3. How do I choose the right bare conductor for my project?

Selection depends on voltage level, span length, mechanical load, environmental conditions, and applicable standards.

4. Can bare conductors be customized for utility specifications?

Yes. Manufacturers like HNBF Power provide customized stranding, sizes, and compliance options based on project requirements.

5. What standards apply to bare conductors?

Common standards include ASTM, IEC, and BS, depending on regional and utility specifications.

Power Your Grid with Confidence

Bare conductors remain the backbone of reliable overhead power transmission. Selecting the right conductor and the right manufacturing partner ensures performance, safety, and long-term value for utility and EPC projects.

Contact HNBF Power today to discuss your bare conductor requirements and receive customized solutions engineered for your power transmission and distribution needs.