Owning a tractor is a significant investment, especially for those managing properties or farms in Northern Virginia. To keep your machinery running at peak performance, understanding the subtle hints your engine gives before a total breakdown is essential. If you are currently facing mechanical hurdles, seeking professional Tractor Repair in Centreville, VA, can save you from the exorbitant costs of a complete engine replacement. Early detection is the bridge between a quick fix and a permanent “out of commission” sign on your equipment.

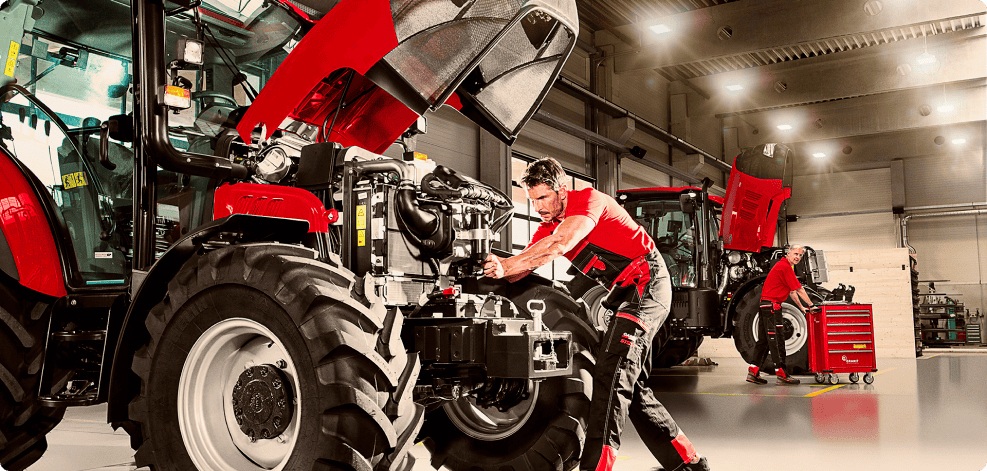

At Liberty Appliance Repair, we understand that a tractor isn’t just a vehicle; it’s the backbone of your daily operations. Whether you are dealing with a compact utility tractor or a heavy-duty farming machine, ignoring small symptoms today leads to catastrophic failures tomorrow.

1. Discoloured Exhaust Smoke

One of the most visual indicators of engine distress is the colour of the smoke exiting the exhaust pipe. While a little puff of black smoke upon startup is common for older diesel engines, persistent discolouration is a red flag.

- Blue Smoke: This usually indicates that the engine is burning oil. This could be due to worn piston rings, damaged valve seals, or a failing cylinder liner.

- White Smoke: Thick white smoke often points to coolant entering the combustion chamber, which is a classic symptom of a blown head gasket or a cracked engine block.

- Black Smoke: This suggests an improper air-to-fuel ratio, meaning the engine is burning too much fuel. A clogged air filter or faulty fuel injectors could cause this.

2. Unusual Noises and Vibrations

A seasoned operator knows exactly how their tractor sounds. Any deviation from that rhythmic hum should be investigated immediately.

Knocking or Tapping

If you hear a metallic “knocking” sound, it often indicates “rod knock,” which happens when there is excessive clearance between the connecting rod bearing and the crankshaft. This is a severe issue that requires immediate attention from a specialist in Tractor Repair in Centreville, VA, to prevent the rod from breaking through the engine block.

Squealing or Grinding

Squealing is often related to a slipping fan belt or a failing water pump bearing. Grinding noises suggest that internal components are rubbing together without sufficient lubrication, leading to rapid wear and overheating.

3. Loss of Power and Performance

If your tractor struggles to pull a load it previously handled with ease, or if it bogs down during routine tasks, your engine is losing its “oomph.”

- Compression Loss: Over time, engines lose compression due to wear and tear on the valves and pistons.

- Fuel System Clogs: A drop in power can also be attributed to a failing fuel pump or clogged fuel filters.

- Turbocharger Issues: For modern turbocharged tractors, a loss of power often stems from a leak in the boost pipes or a failing turbo spool.

Keeping your diesel engine maintenance schedule up to date is the best way to prevent these gradual power losses from becoming permanent.

4. Fluctuations in Oil Pressure and Temperature

Your dashboard gauges are your first line of defence. Never ignore a warning light, even if the tractor seems to be “running fine.”

Low Oil Pressure

Oil is the lifeblood of your engine. Low pressure means the internal components aren’t receiving the lubrication they need. A low oil level can cause this, a failing oil pump, or internal leaks. Running an engine with low oil pressure for even a few minutes can cause irreparable damage to the crankshaft and bearings.

Overheating

Tractors operate under high stress, but they are designed to manage heat. If your temperature gauge is consistently hitting the red zone, you might have a clogged radiator, a stuck thermostat, or a leaking cooling system. Constant overheating warps engine components and leads to the dreaded cracked cylinder head.

5. Difficulty Starting the Engine

If your tractor takes multiple tries to turn over, or if it struggles to start in relatively mild weather, the engine is likely signalling an internal struggle. While it could be a simple battery or starter motor issue, it often points to deeper problems like:

- Low Compression: The engine can’t generate enough heat/pressure to ignite the fuel.

- Fuel Delivery Issues: Air might be trapped in the fuel lines, or the injectors might be fouled.

- Glow Plug Failure: In diesel engines, faulty glow plugs make cold starts nearly impossible and put extra strain on the entire system.

6. Increased Fluid Consumption

Are you topping off the oil or coolant more often than usual? Even if you don’t see a puddle on the barn floor, your engine might be “consuming” these fluids internally.

- Coolant in the Oil: Check your oil dipstick. Suppose the oil looks like a “milky latte,” and coolant is leaking into the oil system. This is a critical failure that requires a professional agricultural equipment mechanic.

- Oil Leaks: Inspect the gaskets and seals. Small seeps can quickly turn into major leaks under the high-pressure environment of a working engine.

Why Professional Intervention Matters

Attempting a “DIY” fix on a complex tractor engine without the right tools can often lead to more harm than good. Modern tractors utilise sophisticated electronics and high-pressure fuel systems that require precision calibration.

By catching these signs early and contacting Liberty Appliance Repair, you ensure that your machinery receives the expert care it needs. Whether it’s a routine tractor tune-up, a cooling system flush, or a complex engine overhaul, timely maintenance extends the lifespan of your equipment by years.

Summary Checklist for Operators:

- Check oil and coolant levels before every shift.

- Clean the radiator screen daily in dusty conditions.

- Listen for changes in engine pitch or rhythm.

- Monitor exhaust smoke colour during heavy loads.

- Keep a log of all heavy equipment repairs and service dates.

Regular inspections are the most cost-effective way to manage your fleet. Don’t wait for the engine to seize in the middle of a busy season.