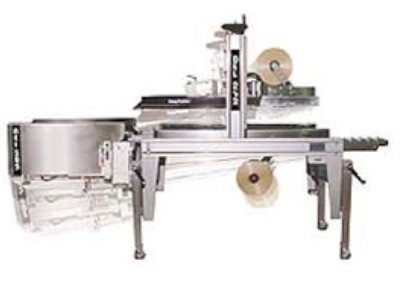

In today’s competitive manufacturing and packaging industries, efficiency, reliability, and consistency are essential for success. Belcor has established itself as a trusted provider of industrial machinery, offering a range of packaging and production solutions that help businesses optimise operations. From case sealers to automated production lines, Belcor machinery is designed to meet diverse industrial needs while delivering long-term durability and performance. Understanding its features, benefits, and applications can help manufacturers make informed operational decisions.

Key Features of Belcor Machinery

Belcor machinery is designed for precision and flexibility, incorporating features that enhance performance and efficiency. Some of the most notable features include:

- Automated Case Sealing: Many Belcor models offer fully or semi-automatic case sealing, enabling consistent, reliable tape application with minimal operator intervention.

- Durable Construction: Belcor machines are built from high-quality materials, ensuring long-term durability and resistance to wear and tear, even in high-volume production environments.

- Adjustable Settings: Equipment can be customised to accommodate a variety of box sizes, tape widths, and production speeds, providing flexibility for different packaging needs.

- User-Friendly Controls: Intuitive control panels and programmable interfaces allow operators to easily manage machine functions, reducing training time and minimising errors.

- Integrated Safety Features: Safety mechanisms, including emergency stops and protective guards, ensure operator safety while maintaining efficient operations.

Benefits of Using Belcor Machinery

Investing in Belcor machinery provides several advantages for manufacturers and packaging operations.

- Enhanced Productivity: Automated and semi-automated systems reduce manual labour, increase production speed, and maintain consistent output quality, allowing businesses to meet high-volume demands efficiently.

- Cost Efficiency: By minimising material waste, optimising labour use, and reducing downtime, Belcor machines contribute to overall cost savings for manufacturers.

- Reliability and Durability: The robust construction and high-quality components of Belcor machinery ensure long-lasting performance, reducing maintenance costs and operational interruptions.

- Flexibility for Various Applications: Adjustable settings and versatile designs enable manufacturers to handle a range of box sizes and product types without requiring multiple machines.

- Safety and Compliance: Integrated safety features protect operators and help companies comply with workplace safety regulations, reducing liability and potential downtime from accidents.

- Consistent Quality: Belcor machinery ensures uniform sealing and packaging, reducing product damage and maintaining high-quality standards throughout the production line.

- Scalability: Businesses can easily scale their operations by integrating Belcor machines into expanding production lines or adapting to higher-volume packaging needs.

- Energy Efficiency: Many Belcor models are designed to operate efficiently, lowering energy consumption and reducing operational costs over time.

- Reduced Training Time: User-friendly controls and intuitive interfaces make it easier for operators to learn the system quickly, minimizing disruptions during onboarding.

Applications of Belcor Machinery

Belcor machinery is widely used across multiple industries, making it a versatile solution for a variety of packaging and production needs. Some common applications include:

- Case Sealing: Belcor case sealers are ideal for efficiently sealing corrugated boxes in the food and beverage, electronics, and consumer goods industries.

- Packaging Lines: Belcor machines integrate seamlessly into automated production lines, facilitating the movement, sealing, and labelling of products.

- Warehousing and Distribution: High-volume distribution centres benefit from Belcor machinery that streamlines order fulfilment and packaging.

- Manufacturing Facilities: From automotive components to small consumer products, Belcor equipment supports consistent packaging and protection of goods before shipping.

Maintenance and Support

Proper maintenance of Belcor machinery ensures optimal performance and longevity. Regular preventive maintenance, including cleaning, inspection, and lubrication, helps prevent breakdowns and keeps production lines running smoothly. Belcor also offers comprehensive customer support, including training, technical assistance, and access to replacement components, ensuring that operations remain efficient and reliable.

Conclusion

Belcor machinery provides manufacturers and packaging facilities with durable, efficient, and versatile solutions that enhance productivity, reduce costs, and ensure consistent output. From automated case sealing to integration with complex production lines, Belcor equipment is designed to meet the rigorous demands of modern industrial operations. Proper use and maintenance maximise efficiency, safety, and longevity. For businesses seeking reliable and high-performance solutions, partnering with a trusted parts machine provider ensures access to the quality machinery and components necessary for long-term success.