When making sure perishables like food, pharmaceuticals, vaccines, and chemicals are not damaged, strict temperature control along the global supply chain is needed. A minor mistake in processing can result in waste, losses, or dangers to one’s health. Monitoring and protecting temperature-sensitive products as they move and are kept during storage have improved due to IoT technology.

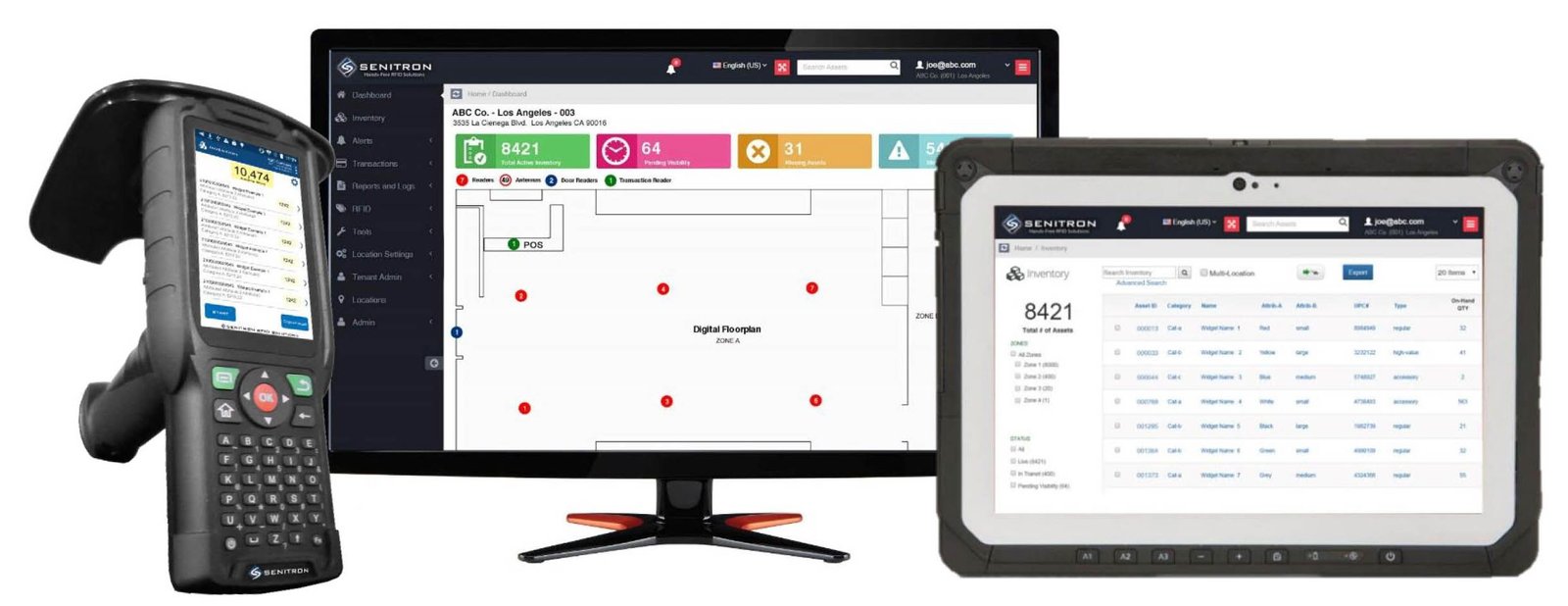

This post looks into what IoT-based cold chain systems are, compares them to RFID, shows their location, highlights their main advantages, and shares tips on implementing these systems. Check a reliable RFID software platform to manage everything remotely.

Learn about Cold Chain Management

IoT uses technology such as smart sensors, GPS trackers, and cloud analysis in cold chain management to oversee temperature, humidity, and location in the present moment. It is different from manual checks because it gives real-time monitoring all along the supply chain, from producing the goods to delivering them, supporting better control and accuracy with perishable products.

Working Principle

Intelligent sensors on shipments always measure temperature and humidity; at the same time, GPS keeps an eye on where and how the goods are moving. If the data collected shows readings beyond the set boundaries, the cloud analytics generator will alert those in charge. The addition of blockchain support as an option makes the logs irreplaceable and helps maintain the quality of perishable goods by boosting everyone’s confidence.

How is IoT Different from RFID?

Even though they both monitor items in cold chain logistics, they are used for different purposes.

- IoT allows quick and constant monitoring because of its advanced sensors and cloud capabilities, which help preserve perishables, vaccines, and other valuable items.

- Unlike barcodes, RFID lets you scan products and keeps track of them in batches and inventories.

- What RFID does best is simple tracking, but only IoT can make sure the environment is proper and the product is safe during transport.

Where to Use This Technology?

Some of the common uses of IoT technology are-

a) Medical Field

The use of IoT technology in the cold chain guarantees that COVID-19 vaccines, insulin, and biologics are kept at the correct temperature, making them work well. It also helps to stop over $35 billion in losses that occur every year because of spoiled medical products kept at controlled temperatures.

b) Food Industry

IoT tracks everything from meat to fish and fresh vegetables so that the best environmental conditions can be maintained. Real-time observation makes sure food is kept safe, as it greatly lessens the chance of foodborne illnesses that may result from temperature changes or bad handling along the way.

c) Chemical Factories

Lab samples, enzymes, and reagents are monitored using IoT, keeping them stable and effective since temperature is important for them. Thanks to real-time monitoring, the main research and medical work is kept safe from damage caused by exposure. The use of effective RFID inventory software is going to be vital.

d) For Horticulture

With IoT, flowers, plants, and seeds are kept properly during storage and transportation since the temperature and humidity are consistently monitored.

By using the Internet of Things, cold chain logistics is changing from responding to problems to addressing them first. RFID, on the other hand, just tracks where things are; IoT is active all the time and constantly checks the surroundings to keep items safe and avoid damage.