Motor starting is one of the most punishing moments in any electrical system. In Canadian environments, that stress multiplies. Long shutdown periods, extreme cold, and unstable supply conditions expose weaknesses that remain hidden in milder climates. Understanding Motor Start Capacitors in canada requires hands-on knowledge of how motors behave at startup, how components degrade, and how poor selection decisions ripple into repeated failures.

Cold Starts: Where Most Designs Are Truly Tested

At low ambient temperatures, lubricants thicken, mechanical clearances tighten, and rotor inertia increases. Motors draw higher current for longer periods while trying to overcome this resistance. The start capacitor must deliver sufficient phase shift and torque without overstressing itself.

Professionals working with Motor Start Capacitors in canada account for:

- Extended acceleration time during winter startups

- Higher internal heating during capacitor engagement

- Increased stress on potential relays and centrifugal switches

Ignoring these factors leads to nuisance trips that are often misdiagnosed as motor failure.

Why Microfarads Alone Don’t Define Suitability

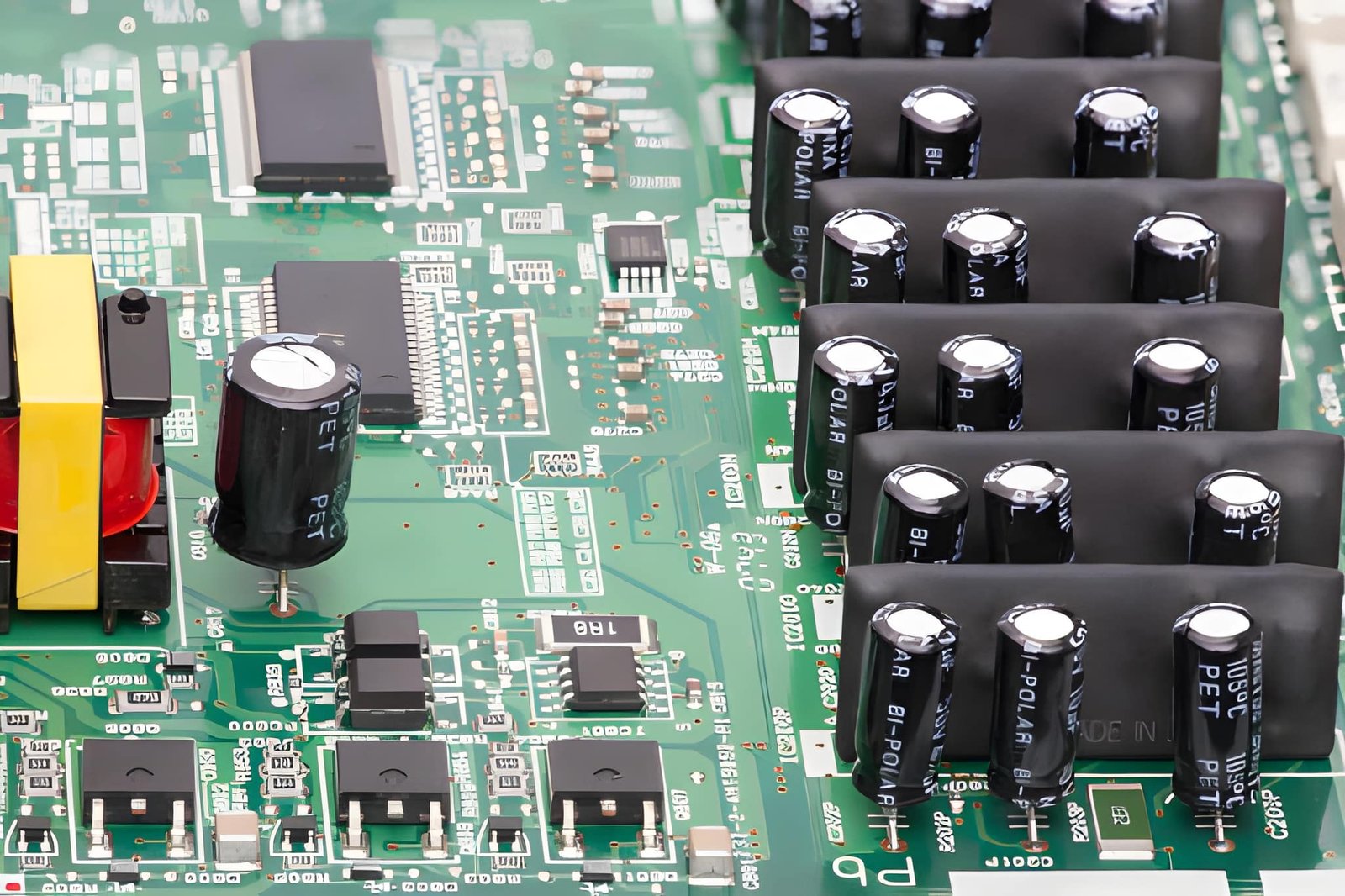

Catalog specifications emphasize capacitance and voltage, but real-world reliability depends on construction quality and duty tolerance. Two capacitors with identical ratings can behave very differently under cold-start conditions.

Experienced technicians selecting Motor Start Capacitors in canada evaluate:

- Dielectric film resilience at low temperatures

- Internal pressure-relief reliability

- Terminal strength under vibration

- Capacitance stability during repeated starts

Suppliers such as En-Trade are valued because they understand these differences and guide selection accordingly.

Start Capacitor Duty Cycle: The Silent Killer

Start capacitors are designed for intermittent duty. Problems arise when motors struggle to reach speed quickly, keeping the capacitor engaged longer than intended. This accelerates dielectric breakdown and causes premature failure.

Professionals managing Motor Start Capacitors in canada focus on reducing engagement time by:

- Correcting mechanical load issues

- Verifying proper relay operation

- Ensuring adequate supply voltage

Replacing the capacitor without addressing these root causes guarantees repeat failures.

Common Failure Patterns Seen Across Canada

Field data reveals consistent seasonal patterns. Early winter startups after long idle periods account for a disproportionate number of capacitor failures.

Typical failure modes include:

- Bulging cases from internal gas buildup

- Capacitance drift causing weak starting torque

- Burned relay contacts from prolonged engagement

- Complete dielectric rupture during repeated cold starts

Upgrading to higher-quality Motor Start Capacitors in canada significantly reduces these incidents.

Voltage Quality and Its Direct Impact

Voltage sag during startup increases the time a capacitor remains engaged, compounding internal heat buildup. Rural and industrial sites are particularly vulnerable.

Experienced practitioners often specify:

- Higher voltage-rated capacitors for added insulation margin

- Start relays matched to real inrush characteristics

- Voltage verification during peak demand periods

These practices extend the service life of Motor Start Capacitors in canada well beyond average expectations.

Oversizing: A Common but Risky Shortcut

Installing a larger capacitor to “help the motor start” is a frequent field decision—but not always a smart one. Excessive capacitance raises starting current and stresses windings and switching components.

Professionals size start capacitors based on:

- Motor design and winding configuration

- Load inertia and startup profile

- Manufacturer torque recommendations

Precision, not excess, defines reliable starting.

Storage and Shelf Life: Failure Before Installation

Capacitors degrade quietly when stored improperly. Cold warehouses, high humidity, and extended shelf time all shorten lifespan before the unit is ever energized.

Best practices include:

- Climate-controlled storage

- FIFO inventory rotation

- Visual inspection before installation

Organizations sourcing Motor Start Capacitors in canada increasingly evaluate supplier storage practices—not just pricing.

Preventive Replacement Strategy

Because start capacitors fail suddenly, many professionals replace them proactively during major maintenance cycles, especially in mission-critical systems.

This approach:

- Prevents secondary motor damage

- Reduces emergency service calls

- Improves operational predictability

Suppliers like En-Trade often support this strategy by maintaining consistent product availability.

When Capacitor Failure Signals a Bigger Problem

Repeated capacitor burnout often indicates deeper mechanical or electrical issues. Binding compressors, failing bearings, or incorrect refrigerant charge can all extend start duration.

Experts treat capacitor failure as diagnostic evidence—not the root cause.

Final Perspective

Motor starting lasts only seconds, but its consequences echo across the system’s lifespan. In Canada’s harsh operating environment, disciplined selection and management of Motor Start Capacitors in canada protects motors, reduces downtime, and stabilizes maintenance costs.

Working with knowledgeable suppliers such as En-Trade ensures capacitor selection is guided by real operating conditions rather than assumptions or shortcuts.

FAQs

1. Why do start capacitors fail more often in cold climates?

Cold increases startup torque demand and engagement time, raising internal heat and electrical stress.

2. Does using a higher voltage-rated capacitor improve reliability?

Yes, it provides greater insulation margin and resistance to voltage fluctuation.

3. Can oversizing a start capacitor damage the motor?

Yes, excessive capacitance increases inrush current and stresses windings.

4. Should start capacitors be replaced preventively?

Many professionals replace them during scheduled maintenance to avoid sudden failures.

5. How does En-Trade support proper capacitor selection?

By aligning component choice with real startup conditions, storage integrity, and application demands.