Every time you start your vehicle or boat, a precise and powerful mechanism is activated to bring the engine to life. At the heart of this process is the starter motor, a compact but essential component responsible for initiating engine operation. Though often overlooked, the starter motor plays a vital role in ensuring reliable starts and seamless performance.

This blog explains what a starter motor is, how it works, the different types available, signs of failure, and tips for maintenance and replacement.

What Is a Starter Motor?

A starter motor is an electric motor that engages the engine’s flywheel to initiate its operation. It draws electrical energy from the battery and uses it to turn over the engine until internal combustion begins. Once the engine starts running on its own, the starter motor disengages automatically.

How Does a Starter Motor Work?

Here’s how the starting process works step-by-step:

- Ignition Activated

When the key is turned or the start button is pressed, power is sent from the battery to the starter solenoid. - Solenoid Engagement

The solenoid pushes the pinion gear forward so it meshes with the engine’s flywheel. - Engine Cranking

The starter motor turns the flywheel, which in turn rotates the crankshaft to initiate combustion. - Disengagement

Once the engine fires and runs independently, the starter motor automatically disengages to prevent damage.

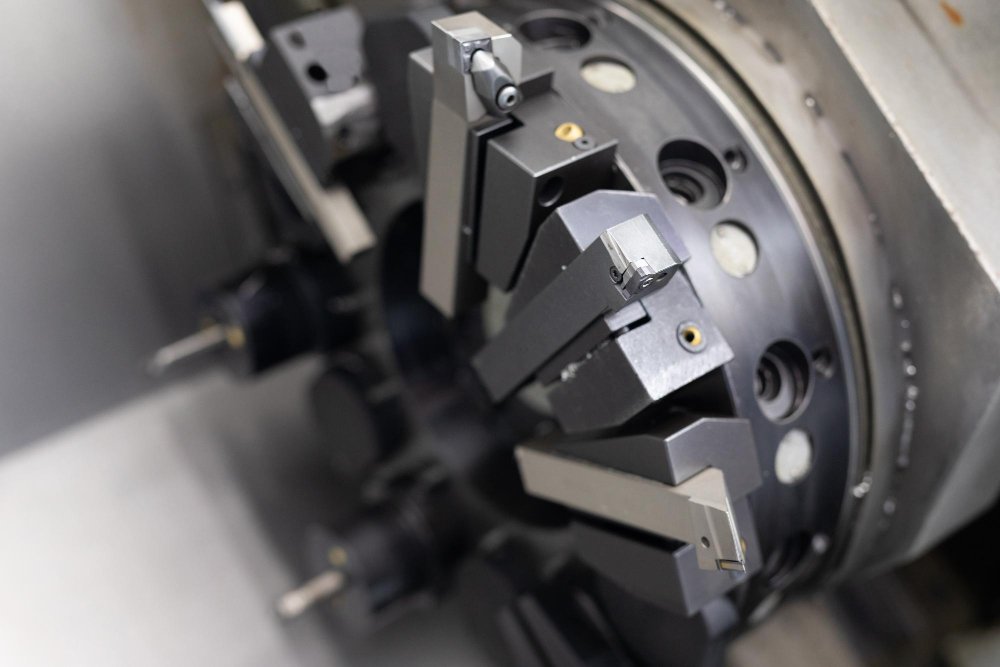

Types of Starter Motors

Starter motors vary based on engine type, size, and application. The most common types include:

- Direct Drive Starter

Traditional design, simple and durable but large and heavy. - Gear Reduction Starter

Uses gears to increase torque, common in marine and diesel engines due to their high compression ratios. - Permanent Magnet Starter

Lightweight and efficient, used in smaller engines and modern automotive applications. - Inertia Starter

Relies on the momentum of the pinion gear, typically found in older machinery.

Signs of a Faulty Starter Motor

Starter motors can wear out over time or fail due to electrical or mechanical issues. Common signs include:

- Clicking noise when turning the key

- Engine fails to crank or cranks very slowly

- Grinding sound during startup

- Smoke or overheating near the starter area

- Intermittent or delayed starting

These symptoms often mimic battery issues, so it’s important to diagnose the problem correctly before replacing parts.

Maintenance Tips for Starter Motors

While starter motors are generally built to last, proper care can extend their life:

- Maintain Battery Health: Weak batteries can overload the starter.

- Check Wiring and Terminals: Ensure clean, tight connections.

- Protect Against Moisture: Particularly in marine environments, corrosion can shorten starter life.

- Inspect for Unusual Sounds: Grinding or whining can signal alignment or gear issues.

- Replace Worn Components Promptly: Early repairs prevent further damage to the flywheel or electrical system.

Marine Starter Motors: Built for Harsh Environments

In marine settings, starter motors face additional challenges like saltwater exposure, vibration, and high engine loads. Marine-grade starter motors are designed with:

- Corrosion-resistant housings

- Moisture-sealed solenoids

- Higher torque output for large displacement engines

- Reinforced internal components for vibration resistance

If you’re operating a vessel in saltwater, always choose a marine-certified starter motor to ensure durability and compliance with industry standards.

Conclusion

The starter motor may seem like a small part of your engine system, but without it, you’re not going anywhere. Whether you’re maintaining a car, truck, boat, or industrial engine, understanding the function and care of the starter motor is key to reliable performance.

If you’re experiencing starting issues or suspect starter motor failure, don’t ignore the signs. Timely maintenance or replacement can prevent larger, more expensive repairs down the line.