Filament tapes are also known as strapping tapes or fiber-reinforced tapes—are high‑strength pressure‑sensitive adhesive (PSA) tapes that embed glass or nylon filaments for superior tensile strength and tear‑resistance. Unlike basic packing tapes, filament tape is engineered to endure heavy loads, resist tearing, and maintain adhesive integrity under stress.

These 3M Tapes typically consists of a film backing (often polypropylene or polyester), a high‑tack adhesive layer, and embedded fiberglass filaments running lengthwise—or in some products, cross‑woven for even greater robustness.

Key Tape Types & Reinforcement Patterns including Filament Tapes:

When choosing filament tape, a critical decision is between one‑way (single‑directional) and two‑way (cross‑woven or bi‑directional) reinforcement:

- One‑Way Filament Tape

Fibers run lengthwise: strong in that direction, cost‑effective, but can split lengthwise due to lack of cross reinforcement. - Two‑Way / Cross‑Weave Filament Tape

Fibers run both length and width: offers superior tear resistance in all directions, preventing splits. More expensive but ideal for heavy duty or irregular loads.

Technical Specifications & Properties

| Feature | Description |

|---|---|

| Tensile Strength | Ranges from ~100 lb/in up to ~600 lb/in width—depending on filament density and tape grade (Wikipedia) |

| Thickness (Caliper) | Typically between 3–10 mil |

| Adhesive Types | Natural rubber (fast tack), synthetic rubber, acrylic (temperature & UV resistance), clean‑removal options (jxgreentape.com, packagingtapedepot.com) |

| Backing Options | Polypropylene (PP), polyester (PET), paper, or specialty coatings; color options include clear, brown, printed (GlobalSpec, packagingtapedepot.com) |

| Environmental Resistance | Many offerings support temperature ranges from –40 °F to +200 °F (–40 °C to ~93 °C), and UV/weather resistance (My WordPress Website, Adherex Packaging) |

Selecting the Right Tape: What to Consider

1. Tensile Strength & Load Needs

Choose a tape rated for at least the stress level of your heaviest packages. For extreme loads, consider grades up to 600 lb/in M-Source.

2. Adhesive Match for Substrate & Conditions

- Natural rubber adhesives deliver fast initial tack—ideal on corrugated, cardboard, or rough surfaces.

- Acrylic adhesives offer superior durability under temperature changes and UV exposure—suitable for outdoor or industrial environments.

- Clean‑removal adhesives leave minimal residue, perfect for temporary holding or parts assembly that must remain clean.

3. Directionality of Reinforcement

- For simple bundling tasks along one axis, one‑way tape may suffice.

- But for unpredictable forces, multi‑directional stress, or heavy pallets, two‑way tape provides unmatched resistance to tearing or splitting (jl3tape.com).

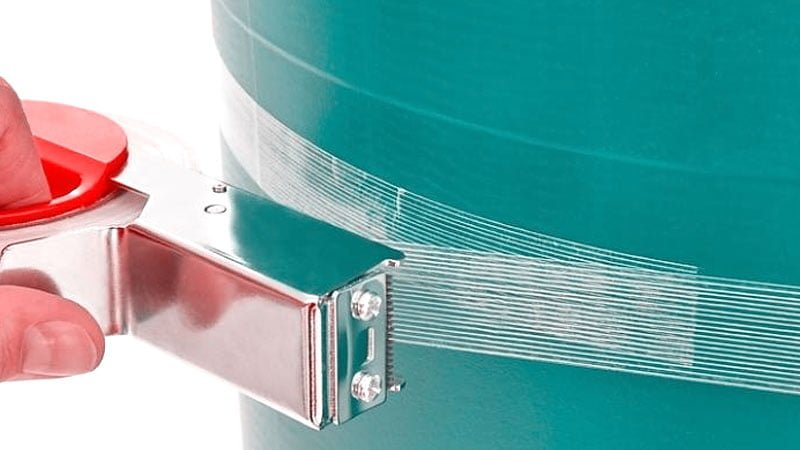

4. Application Methods

- Handheld dispensers are great for low‑volume, flexible use.

- Table‑top or automatic dispensers offer consistent tension, precise cuts, and speed—especially in high-volume or automated workflows.

- Some systems integrate directly into robotic conveyor lines for fully automated strapping (polylinecorp.com, nextgentapes.com).

5. Environmental Exposure

If tape will be exposed to moisture, UV, or temperature extremes, select products rated for weather or chemical resistance—often acrylic‑based or specialty films provide that resilience (jxgreentape.com).

6. Size, Color & Branding Options

Consider tape widths (ranging from ~12 mm to over 96 mm) and custom printing for logos or instructions if needed. Also, tape color (clear, brown, or branded) may help with visibility or product identification (quickpakinc.com, GlobalSpec).

7. Cost & Total Cost of Ownership (TCO)

Initial cost per roll may be ~20–50% higher than polypropylene strapping, but higher strength means:

- Fewer wraps required

- Lower damage rates

- Faster application

- Improved ROI in terms of avoided product loss and labor savings (nextgentapes.com).

Filament Tape vs. Polypropylene Strapping Tape

To clarify: polypropylene strapping tape is a separate format—backed with tensile‑oriented polypropylene, providing stretch rather than rigidity. It’s more suited for cushioning stretch applications and is easier to recycle. Filament tape, by contrast, is rigid, high‑strength, and best for static heavy loads (nextgentapes.com).

| Feature | Filament Tape | Polypropylene Strapping Tape |

|---|---|---|

| Reinforcement | Fiberglass filaments | Tensilized PP fibers |

| Tensile Strength | ~200–600 lb/in | ~50‑100 lb/in |

| Stretch | Negligible (<5%) | Elastic (~20–40%) |

| Tear Resistance | Very high | Moderate |

| Anchor Flexibility | Rigid | Flexible under shock |

| Recyclability | Low (mixed materials) | Higher (single polymer) |

| Cost | Higher initial cost | Lower cost per roll |

| Ideal Applications | Heavy cartons, palletizing, bundling | Light/medium bundles, shock‑absorbent |

Industry Use Cases & Benefits

- Warehousing & Shipping

Use filament tape to reinforce cartons, unitize pallets, and secure loads against shifting. One case study showed a 40% drop in damage claims when switching to bidirectional filament tape for pallet loads (nextgentapes.com). - E-commerce Fulfillment

Bundling cable harnesses or kits using filament tape keeps components neat, prevents damage, and improves the customer unboxing experience by eliminating mess and tangles (nextgentapes.com). - Construction & Manufacturing

Filament tapes can secure insulations, piping, rebar, and conduits—especially useful outdoors due to UV/moisture resistance and high rigidity (My WordPress Website, jxgreentape.com). - Automotive & Electronics

Filament tape helps strap wire looms, bind tubing, and hold heavy parts during assembly or transit. Clean removal variants prevent adhesive residue and protect delicate assemblies (My WordPress Website).

Storage & Shelf Life Best Practices

- Store rolls in a cool, dry environment (ideal 15–25 °C) to preserve adhesive tack.

- Rotate stock via FIFO (first‑in, first‑out) to use older rolls first.

- Avoid stacking heavy pallets on tapes to prevent deformation.

- Expected shelf life: 12–18 months if stored correctly, preserving adhesion and strength (nextgentapes.com).

Safety & Handling Tips

- Wear cut‑resistant gloves, especially with bi‑directional 3M tapes—edges of fiberglass filaments can be sharp.

- Use proper dispensers or cutting tools to avoid injury and ensure clean cuts.

- Follow OSHA guidelines when handling heavy rolls or automated dispensing systems, to prevent strain or injury (nextgentapes.com).

Common Questions (FAQs)

Q: Can filament tape be recycled?

A: Generally no—mixed materials make most filament tapes unsuitable for curbside recycling. Some manufacturers offer biodegradable backings or reclamation programs if sustainability is a priority (nextgentapes.com).

Q: Is filament tape safe for food packaging?

A: Only if it uses FDA‑compliant adhesives and backing materials. Be sure to verify that specific products meet food‑contact certifications (nextgentapes.com).

Q: How do I test a tape sample?

A: Perform simple tensile or tear testing on representative cartons or bundles. For standardized measures, consider ASTM D3759 tensile testing for precise load capacity profiling (nextgentapes.com).

Q: What affects the shelf life of filament tape?

A: Heat, UV exposure, and improper storage reduce adhesive performance over time; properly stored tape typically lasts 12–18 months (nextgentapes.com).

Decision Guide: Quick Summary

- Need maximum strength and rigidity? → Filament tape (prefer cross‑weave for stability).

- Need elasticity and recyclability? → Polypropylene strapping tape.

- Concerned about extreme temperatures or weather? → choose acrylic adhesive, UV‑resistant options.

- Focused on easy, clean removal? → pick a clean‑remove adhesive variant.

- Using high volumes? → invest in automatic or robotic dispensers for speed and precision.

- Prioritize lower total cost, even at higher roll price? → the benefits in reduced damage and efficiency make filament tape attractive.

In Conclusion

Choosing the right filament or strapping tape involves balancing strength, adhesion, environmental needs, application method, and cost. Whether you’re shipping heavy pallets, bundling components for manufacturing, or securing cargo outdoors, the tape you select can significantly impact product security, labor efficiency, and customer satisfaction.

When in doubt, test both tape types on a real use case: apply them to your actual packages or bundles and observe adhesion, tearing, residue, and ease of use. The better performing tape—or combination of tape and dispenser—is the one that works reliably every day without fail.

Armed with this knowledge, you can confidently select the right filament strapping tape to meet your operational demands—and protect your bottom line.